We design and manufacture mechanical seals specifically for the automotive sector.

Production of these products stems from a strong partnership with the manufacturers of the automotive pumps themselves, which allow us to best meet the needs of end customers.

We manufacture mechanical seals that are inserted inside engine cooling system pumps. It is therefore essential that the effectiveness and durability of the seal is maximised to ensure proper functioning of the cooling pump and the vehicle itself.

Meccanotecnica Umbra is aware of all these requirements and that is why all its mechanical seals guarantee a long service life. All mechanical seal materials have undergone extensive preliminary studies. In particular, the sealing rings are manufactured in-house in the company's own production facilities following strict technical and quality procedures.

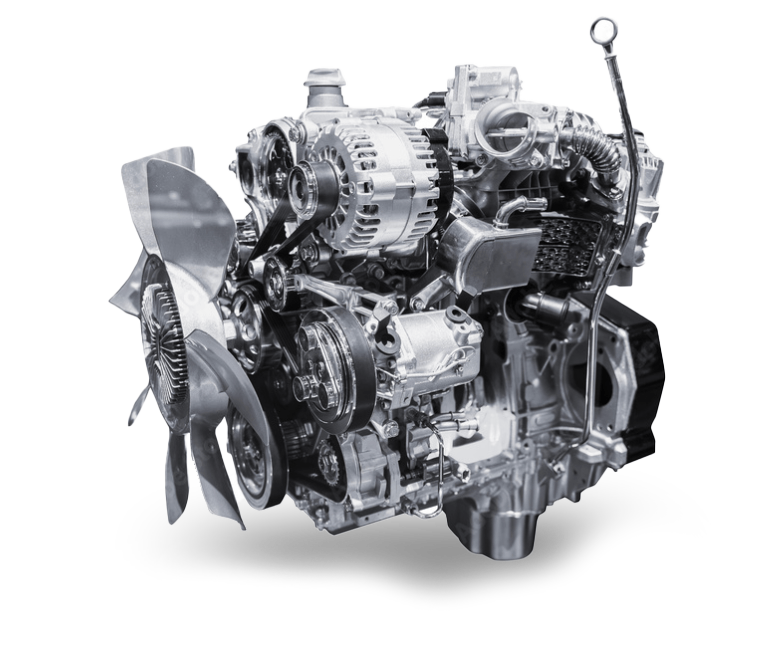

The classics adopted to date, diesel or petrol, are generally equipped with cooling pumps with mechanical drive (via belt or chain or gears), which must operate under sometimes harsh conditions due to the possibility of accidental contamination of the coolant by abrasive particles, which can generate leaks and due to the undesirable presence of vapour phase in the fluid, which reduces cooling and lubrication of the parts in relative motion with overheating and noise. Following the ever-increasing extension of the electrification of auxiliary circuits, typical of hybrid vehicles, electric pumps are also being utilised on this type of engine in order to have circuits capable of ensuring increasingly complex Thermal Management of the entire vehicle, which is useful for increasing engine efficiency and at the same time reducing polluting emissions.

The classics adopted to date, diesel or petrol, are generally equipped with cooling pumps with mechanical drive (via belt or chain or gears), which must operate under sometimes harsh conditions due to the possibility of accidental contamination of the coolant by abrasive particles, which can generate leaks and due to the undesirable presence of vapour phase in the fluid, which reduces cooling and lubrication of the parts in relative motion with overheating and noise. Following the ever-increasing extension of the electrification of auxiliary circuits, typical of hybrid vehicles, electric pumps are also being utilised on this type of engine in order to have circuits capable of ensuring increasingly complex Thermal Management of the entire vehicle, which is useful for increasing engine efficiency and at the same time reducing polluting emissions.

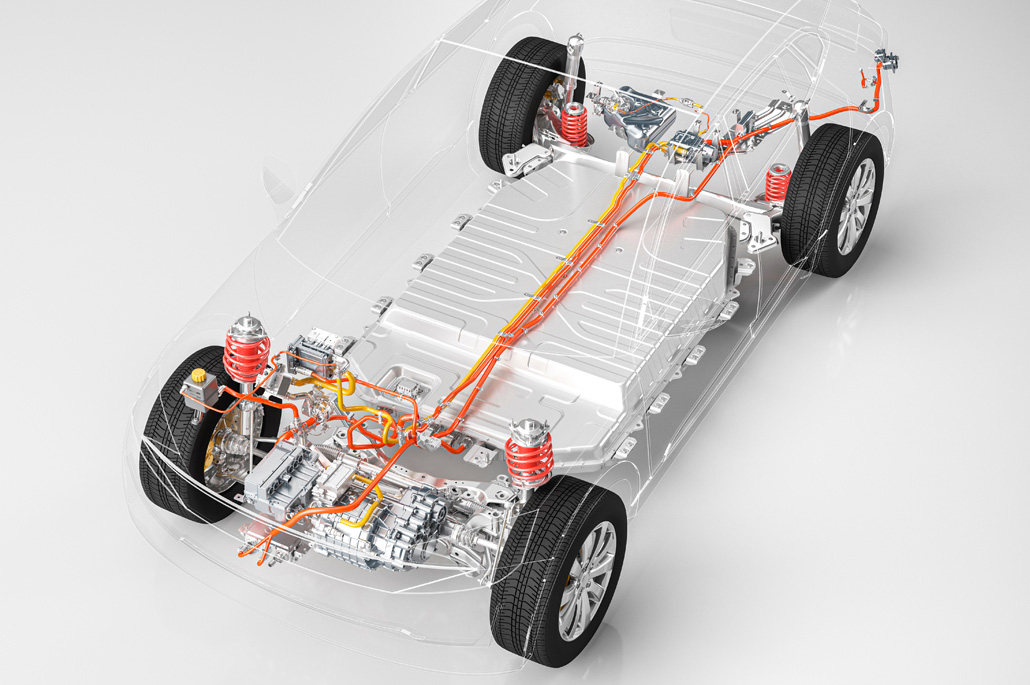

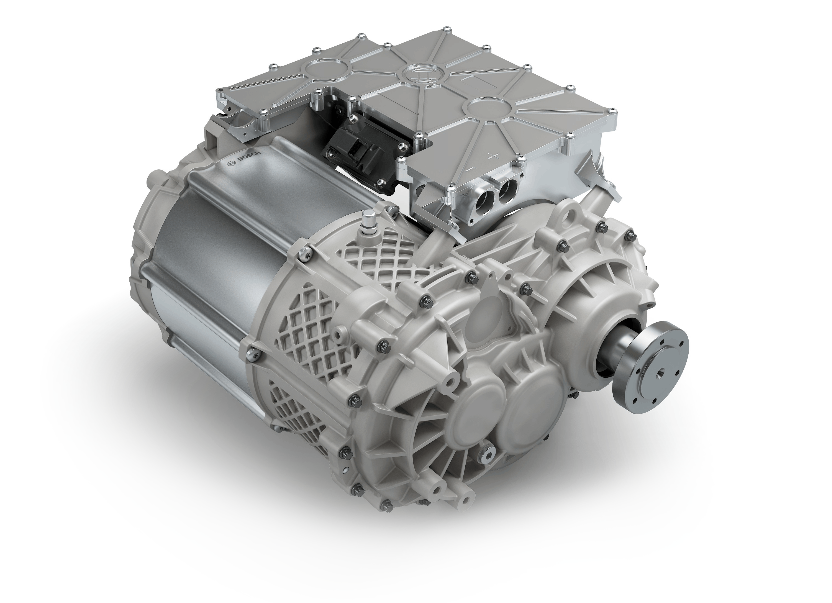

These traction motors, used on hybrid or fully electric vehicles, are generally equipped with several electric pumps for circulating the coolant due to the similar need to optimise Thermal Management, which also affects the battery pack and the electronic circuits of the control units, whose efficiency is greater if the operating regime remains within narrower temperature ranges, with an increase in the possible mileage following each recharge. Therefore, for these pumps, in addition to the effectiveness of the seal and the absence of noise, it is also crucial to minimise the power absorbed to the benefit of the same mileage. To this end, further possibilities for the application of low-friction mechanical seals are being studied and evaluated in Electric Vehicles for internal rotor cooling and transmission lubrication circuits.

These traction motors, used on hybrid or fully electric vehicles, are generally equipped with several electric pumps for circulating the coolant due to the similar need to optimise Thermal Management, which also affects the battery pack and the electronic circuits of the control units, whose efficiency is greater if the operating regime remains within narrower temperature ranges, with an increase in the possible mileage following each recharge. Therefore, for these pumps, in addition to the effectiveness of the seal and the absence of noise, it is also crucial to minimise the power absorbed to the benefit of the same mileage. To this end, further possibilities for the application of low-friction mechanical seals are being studied and evaluated in Electric Vehicles for internal rotor cooling and transmission lubrication circuits.

© 2026 - Meccanotecnica Umbra S.p.A.

Designed by Co.Mo.Do Comunicare Moltiplica Doveri

Developed by NUR Digital Marketing